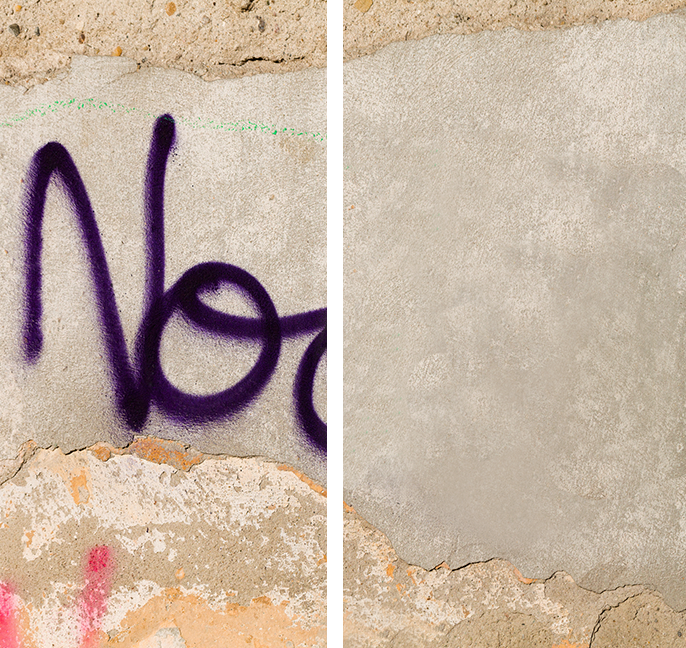

Surface preparation :

-

1Apply the product to a clean, dust-free, grease-free and dry surface.

-

2To remove traces of efflorescence, laitance or grout film, use Guard Cleaner® Surface Preparation.

-

3To remove grease stains, use Guard Cleaner® Maintenance.

-

4Rinse carefully until the surface is free of any trace of cleaner.

Application :

- AntiGraffitiGuard® is prepackaged in the correct ratios. All of

component A must therefore be mixed with all of component B. Under no circumstances modify the A:B ratio. - Before use, thoroughly mix part A (base) using an electric stirrer until a homogeneous liquid is obtained.

- Stirring continuously, add part B (hardener) to part A (base). Blend at moderate speed with an electric mixer for at least 5 min. Leave for 10 min. to allow bubbles to escape, then homogenise again with the electric mixer before application.

- Once prepared, the mixture can be used for 2 hours at an ambient temperature of less than 20°C.

Applying the first coat in two layers:

- In very hot weather: the first coat can be diluted to 10% in clean (drinking) water. Thoroughly homogenise the whole mixture.

- Having first treated the substrate with PrimerGuard®, the product can now be applied to the substrate.

- Leave to dry for 1 hour (assuming a temperature of 20°C).

- Typical coverage on concrete: 60 to 100 g/m² (10 to 16 m²/litre).

Applying the second coat in two layers:

- For better control and ideal results, it is recommended that the 2nd coat be applied with an HVLP spray gun.

- Typical coverage on concrete: 60 to 100 g/m² (10 to 16 m²/litre).

- Protected drying: 24 hours.

- Optimal effects obtained after 5 to 7 days.

For further information, refer to the data sheet and safety sheet.

-

1L

-

5L